The safety of equipment heavily depends on portable appliance testing (PAT). Incidents involving electrical equipment at the workplace and home have recently increased. This implies that safety procedures have worsened, which is just another justification for PAT testing.

The term “portable appliance testing” refers to several electrical tests and inspections performed on portable equipment to make sure it can be used safely. The Inspection and Testing of In-Service Electrical Equipment is also another name for portable testing.

It is significant to remember that running PAT Testing requires more than simply connecting a piece of gear to a PAT tester to determine the result. Also covered by portable appliance testing is keeping records and their recording. Verifying conformity with the Electricity at Work Regulations (EWR) is crucial.

Different Steps for Testing Portable Appliances

The Health and Safety Executive (HSE) recommends three steps for PAT testing:

1. Checking The Equipment

Anyone with electrical equipment should have some basic training on how to use it and check out the warning signs. Users should feel at ease visually evaluating the equipment daily for apparent signs of wear and tear and potential risks, including water hazards or wires tangled under desks.

2. Formal Inspection

A rigorous inspection is only necessary when equipment malfunctions or is used in dangerous settings like theaters, workshops, or laboratories. When formal visual inspection by a certified PAT tester is required for electrical equipment, there may be local laws that specifically address that need. If required, the individual in charge of the area will make arrangements for the inspections.

During the inspection, disconnecting the equipment from the power source and removing the equipment casing or plug cover are required. This ensures that the cable’s and plug’s internal components are securely fastened and connected and that an appropriate fuse with the appropriate rating is installed. No indication of internal harm, overheating, or entry of dirt, dust, or liquid should be present.

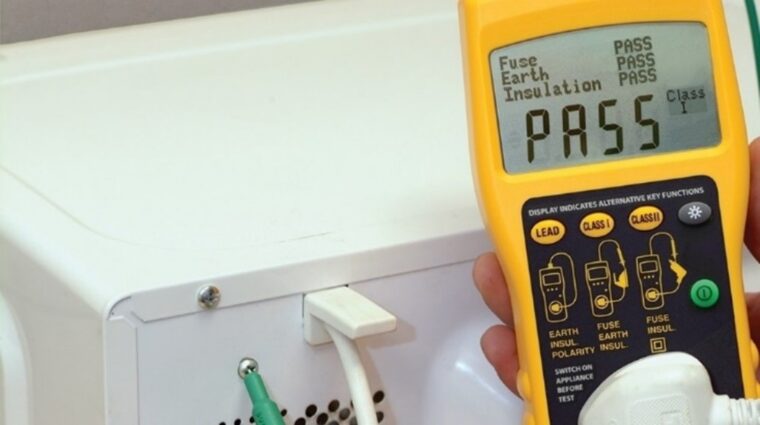

3. Using A Portable Appliance Tester For Manual Inspection

An expert with the required training and tools should do a manual inspection. Utilizing a qualified and experienced PAT tester for the optimum outcome is strongly advised.

The success of the testing, insulation resistance, lead polarity, and ground continuity – all these parameters are required to inspect the appliance. The results will be recorded for future use, and the equipment will be marked with a fail or pass label. It is essential to remove broken appliances as soon as possible so they can be replaced or repaired. Before being utilized again after repair, the item needs to pass another PAT test.

How Can One Define Portable Electrical Equipment?

Electrically connected, moveable, and detachable items are called portable equipment. They frequently come with a plug and a cable line. Hairdryers, computers, cookers, cleaning equipment, and freezers are examples of portable equipment.

Depending on the level of user protection they offer, portable electrical equipment is categorized as Class I or Class II. Although tested differently, both require PAT checks to ensure ongoing safety.

What Appliances Require Testing For Portable Appliances?

Portable appliance testing is essential for most devices that store or discharge energy. Understanding equipment classification is essential for determining whether testing is required.The two main classifications of electrical equipment are double-insulated and earthed.

1. Electrical Class I Item

This type of equipment depends on earth connectivity and has little insulation for safety. An electrical shock could occur if the equipment malfunctions without the earth connection. Class I equipment includes electric warmers, kettles, irons, and toasters. The most dangerous equipment is Class I; hence more frequent testing is required.

2. Electrical Class II Item

Class II equipment is safer than class I since the ground does not shield it. These appliances are much safer because they have double insulation layers. Examples of class II equipment are power tools, lighting, TVs, and hairdryers. Class 2 poses less of a threat. This does not, however, make testing unnecessary.

3. Electrical Class III Item

Batteries-operated appliances and other extra-low voltage equipment fall under Class III. Digital cameras and cell phones are such instances. These appliances typically don’t need to be tested.

What Is The Need For PAT?

An individual’s property will be safe for workers and others exposed by implementing PAT into the appliance risk controls. Electric shocks, flames, and burns are the three most significant risks of malfunctioning equipment.

1. Getting Electricity Shock

An electric shock results from completing a circuit from an electrical source to the ground or the earth. The electric current suddenly passed through human bodies can harm the muscles and nerves and even temporarily paralyze the body. Cardiac arrest is another possibility because the heart is powered by electricity.

2. Burns

When an arc flash comes into contact with skin tissue, it can instantly burn it due to the high temperatures it can reach. The greater voltages and longer contact times could cause inside tissues to burn, causing irreversible organ damage.

3. Fires

Faulty appliances and plugs are one of the leading causes of fires. This occurs when a frayed cable from an outdated gadget carries heat to flammable materials like floors, carpeting, or drapes.

After PAT, What Next?

One will get a report after the portable appliance inspection and testing. The report contains the following details:

- An inventory listing each appliance’s type, location, name, and description.

- A detailed list of test results for each piece of equipment.

- A comprehensive record of everything that failed and a justification for why it happened.

- Each appliance must have a visible pass or fail sticker with the inspector’s signature, the subsequent test date, and the upcoming inspection date.

- If the individual needs more technical expertise, the contractor or knowledgeable individual who carried out the inspection and testing will discuss the report and offer advice on any additional steps that could be required.

Is Pat Testing Required For New Equipment?

If the equipment is new and wasn’t used, it should be marked “new to service,” which means it’s ready for testing when the next inspection comes around. It’s essential to remember that new products might still fail safety tests, have poor wiring, and pose a risk of electrical shock. To protect the security of the business, it is advisable to test and tag new equipment.

Conclusion

Safety is the first thing that comes to mind when discussing PAT testing. PAT testing is essential to ensure that safety regulations are followed when using electrical devices. Remember that it is better to be cautious than sorry, especially given the recent uptick in selling fake electrical items.

When purchased, ensure that any electrical equipment has completed portable appliance testing. Regular PAT testing ensures that all safety rules are always followed.