Commercial factories worldwide are a complex arrangement of equipment and pipeline to connect its various parts, mostly to carry liquid or gas from one area to another during the entire manufacturing process. Flow meters are of multiple types. The generally commonly used types are Obstruction for differential pressures quantification, Inferential or Turbine kinds, Electromagnetic kinds, Positive displacement low flow meter, Fluid Dynamic or Vortex Shedding categories, Anemometer, Ultrasonic and Mass Flow Meter. The Flow Meter is used in each of these areas to quantify flow with the help of sensors for their measurements like linear, nonlinear, mass, or volumetric flow rate of gas or any other liquids.

Flow is usually measured by measuring the velocity of fluid or gas that passes through a known area. In case of very large flow, Tracer methods are typically employed to check the flow rate by ascertaining the changes in concentration of a dye or radioisotopes. You can get more information, including professional advice for installing your flow meter, right here at www.silverinstruments.com so that you may order the same online.

Installing High-Quality Reliable Flow Meters

Only a high-quality and reliable flow meter can ascertain the proper quantification of the liquid or gas flow. If a factory uses a wrong meter or sub-standard one, it can have a devastating effect on its overall production and profitability. In factories, it is a vital part of processing chemicals, and therefore choosing a trustworthy source for your purchase is the first step to make the supply chain smooth and hassle-free.

Your next step while looking for a reliable flow meter low flow rate is the prices as they vary with different manufacturers. Hence, it is better to choose from reputed sites like the above for your requirements. At Silver Instruments, they are sold at factory-direct prices and therefore much lower than that of competitors. Above all, you will find the meters are environmentally friendly and durable.

Basic Flow Meters to High-End Meters

Mass flow is important during any process in a factory as it eliminates inaccuracies caused by the physical properties of a fluid that passes through the pipelines. Again, mass is not affected by changing temperature and pressure, and therefore you need to get the right measurement for the liquid or the gas. It is calculated based on the volume of fluid that passes through a given cross-sectional area per unit of time. A high degree of accuracy is needed when the flow rate has to be measured very minutely to ensure that the fluid control processes are running smoothly, safely, and economically.

There is also a volumetric liquid low flow flowmeter that is used for very low flow ranges. Here, the instruments are operated by using ultrasound in a small and straight tube. It is also used for measuring a wide range of liquids independent of fluid density, temperature, and viscosity. However, if your factory needs to measure only the quantity of liquid that passes through a pipeline, then a very basic flow meter will be enough. On the other hand, mini flow meters are used if the same is for quantifying intricate flows and different anomalies in the flow.

A digital gas flowmeter is installed in large refineries and other major chemical factories to get minute details of gas flow and lower the risk of danger to human lives and damages. Hence, it is necessary that you only install a flow meter after ascertaining the reason for the same and whether your factory needs a basic one or a more accurate one. Simple flow meters can provide 5% accuracy approximately while turbine flow meters are in the range of +_0.5% and +_0.1%.

Understanding Behaviors of Gas or Liquid

The prime reason why a certain low flow flow meter is chosen is by determining first the behavior of gases or liquids in a pipeline. It is noteworthy that every gas or fluid will behave differently when passed through the pipeline. It is due to the viscosity of the liquid, and hence you buy a standard flow meter knowing well how the liquid in the pipelines behave.

If you need suggestions, then the above site has professional staff who can tell you the various types of flow meters that you can use or whether only one suitable type is applicable in your case. If you decide to purchase a turbine flow meter, you should know that it contains a freely suspended rotor and will rotate, determined by the flow velocity. The faster the fluid moves through the pipeline, the more pulses are generated and duly recorded by the meter that instantly provides the reading. Although the turbine flow meter accurately measures the flow, it is good for pure materials only and not for viscous materials. Lastly, this kind of turbine flow meter will need regular servicing and recalibration.

If your factory is not using liquids, but gas then a standard gas flow meter will enable you to determine the behavior of the gas in the pipeline.

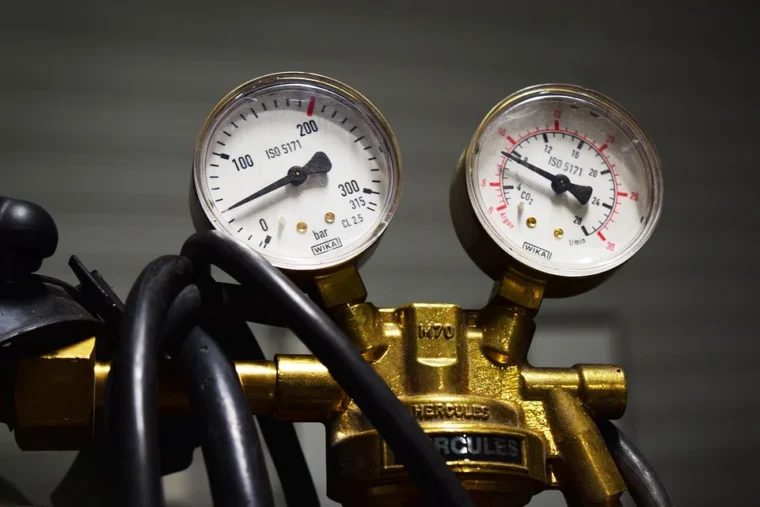

Instruments for Checking Flows, Temperature, and Pressure

At Silver Instruments China, you can get a range of high-quality instruments, including flow meters to thermocouples, at very competitive prices. In the case of temperature measurements, you can buy directly by placing your order for thermocouples and RTD, temperature transmitters, and thermometers. If you need a flow meter for low viscosity, then microflow meter liquid is the best choice. Its measuring element is based on the double-ring piston meter principle. It reacts even to tiny volume flows and is very suitable for dosing and filling systems.

As for pressure and level measurements, you can find pictures of pressure gauges, pressure transmitters, ultrasonic level meters, hydrostatic level meters, and radar level meters at the site. You can also go over the pictures and prices of panel meters and Paperless Recorder as the same is of high quality and are suitable for any organization. In short, a paperless recorder is a data logger or data acquisition device to record measurement data over some time. It is integrated into the general industrial control system for the mandatory process monitoring application.