In this article, we will be discussing the five elements that make up a robotic arm. There are many different types of robotic arms on the market today, but they all share some standard features. We will look at each of these features and explain what they do. By understanding the five elements that make up a robotic arm, you can select the best arm for your needs.

What is a robotic arm, and what are its uses?

A robotic arm is an automated machine to manipulate and move objects, such as tools or materials. It can be used in many different applications, including manufacturing, industrial automation, medical purposes, and home and domestic purposes.

The five elements that make up a robotic arm

Here are the five elements that make up a robotic arm:

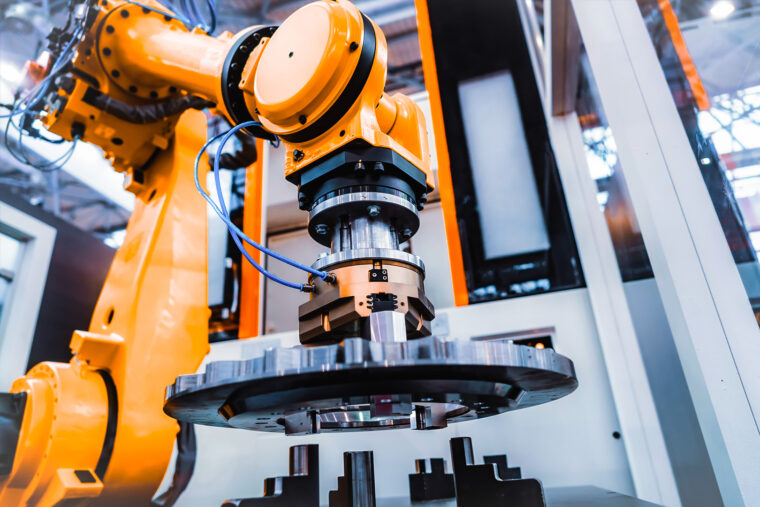

1. End Effector

This is the part of the robotic arm that interacts with the environment, such as a tool or material. It can be as simple as a gripper to hold objects in place or have more complex features like camera vision systems built in.

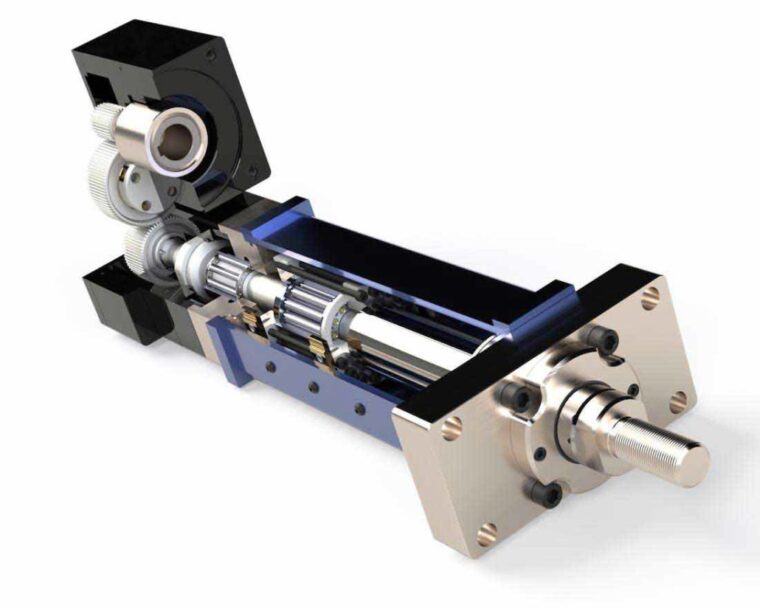

2. Actuators

These are the parts of the arm that move it. Actuators are usually electric or pneumatic and provide the motive power for the robotic arm to manipulate objects.

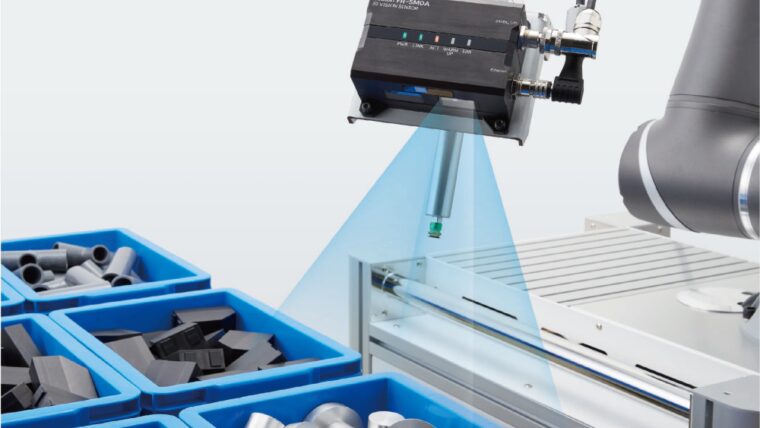

3. Sensors

Sensors send information back to the robot about its environment, such as force, distance, temperature, and position. It helps the robot to understand its surroundings so it can act appropriately.

4. Control System

The robot’s brain receives information from sensors and tells the actuators how to move. It is generally a computer system that uses software programs to control the robotic arm.

5. Power Supply

The power supply provides energy to all the components of the robotic arm, including motors, actuators, and sensors. It may be a battery, AC, DC, or even solar energy.

Robotic arms are widely used in the manufacturing and industrial sectors as they provide increased efficiency with accuracy and precision when carrying out repetitive tasks. They can also be used in medical applications such as surgery, where accuracy and precision are essential. Robotic arms have become increasingly popular in the home and domestic market, with applications such as gutter cleaning or lawn mowing becoming more common.

The different types of robotic arms available on the market

Robotic arms come in different sizes and configurations, each tailored to specific tasks. The most popular types include articulated robotic arms, delta, and SCARA robots. Articulated robotic arms have a wide range of movement and are suitable for jobs that require more skill than others.

Delta robots are fast-moving and have a smaller workspace, making them perfect for high-throughput tasks such as assembly line work. SCARA robots have a limited range of movement but are precise and accurate, making them ideal for pick-and-place activities.

How to choose the right robotic arm for your needs

When choosing the right robotic arm for your needs, it is vital to consider the types of tasks you will be carrying out and the environment in which you work. You should also consider the arm’s size, weight, power requirements, and range of movement. The type of end effector you need will also dictate which robotic arm is best for you.

How to set up and use a robotic arm

Setting up and using a robotic arm is easier than it may seem:

- Mount the arm onto a base and connect any cables or power supplies.

- You will need to program the robotic arm with instructions so it can carry out its tasks accurately and safely.

- You should test the robot to ensure it is working correctly and following all your instructions.

Conclusion

Robotic arms are a great way to automate processes and reduce the need for human labor. They can be used in manufacturing, industrial automation, medical applications, and home and domestic settings.

When choosing the right robotic arm for your needs, you must consider the type of tasks you will be carrying out, the power requirements, and the range of movement needed. Once setup is complete, you should always test that your robot is functioning optimally. With proper use and maintenance, robotic arms can provide exceptional accuracy and reliability for many years.