Because waterjet cutting does not affect the structure of your raw materials, it has been gaining a lot in popularity with machinists. Many clients have had issues with waterjet costs.

Many fabricators feel that waterjet is too expensive and prefer to use traditional methods. While this may be true in certain cases, waterjet efficiency is well worth the cost. Waterjet prices might not be as expensive as you think.

Let’s talk about the various factors that affect the calculation of waterjet costs, and how machinists determine the cost.

What is Waterjet cutting?

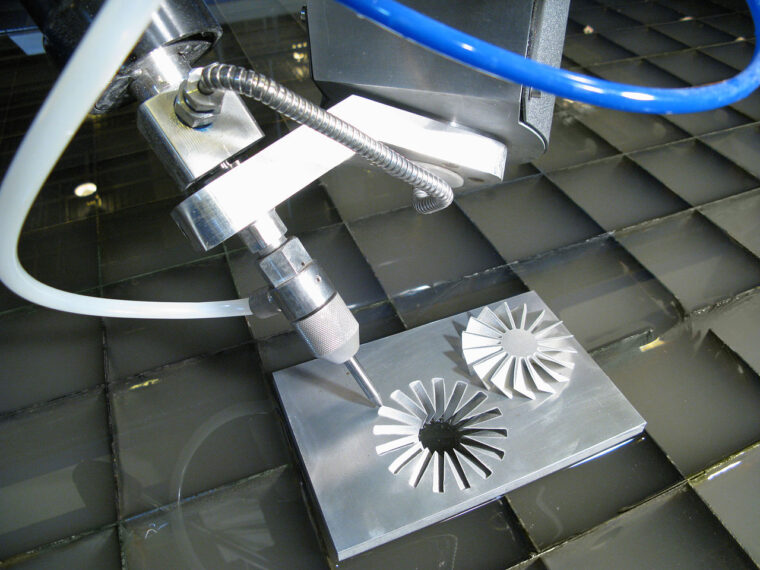

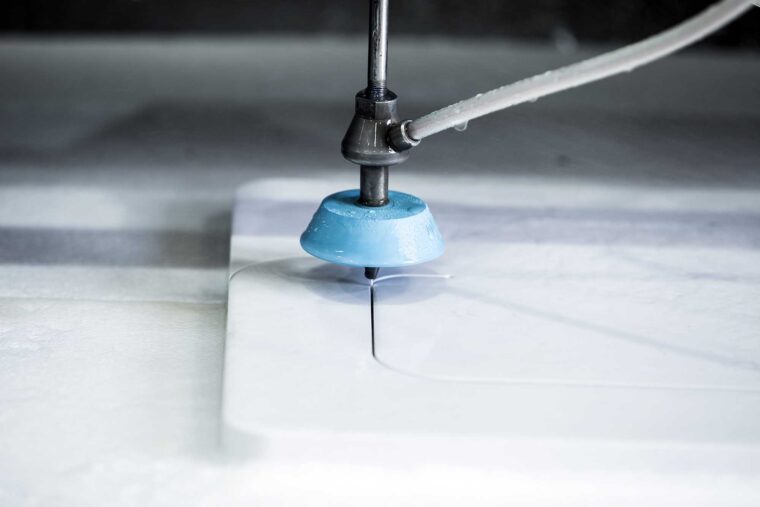

A water jet is also called a waterjet cutter. It is used by machinists to cut a variety of materials and bulk materials. This is done by using water jets that have extremely high pressure. It can also mix water with an abrasive material for cutting. It is used by machinists in sheet metal cutting. More information about this you can find on techniwaterjet.com.

Abrasive jet is a mixture of water and an abrasive material to cut hard metals, stones or glass. It is also known as a pure waterjet, or water-only if the water used to cut materials is ordinary water. This is used when you are cutting soft materials. These materials include rubber, wood, and other soft materials.

Waterjet cutting is used by machinists to fabricate machine parts. It can be used if the material being cut is very sensitive to temperature. Other cutting methods, such as laser cutting, use high heat. Water jets are used by fabricators to cut materials such as aluminum, plastics and rubber.

Waterjets are capable of achieving high precision when cutting down to 0.005 inches (0.13mm). You can get a high level of precision down to 0.001 inches (0.25 mm).

Factors to Consider When Calculating the Waterjet Cost

Before deciding whether waterjet is right for them, machinists must consider the cost of waterjet. Many fabricators are unable to see the differences in operating costs between a plasma cutter and a waterjet. This article will provide answers. It’s possible to determine if you have the financial means to afford this manufacturing process by knowing the price of water jets and their cost of operation.

Here are some cost factors to be aware of if you want to use a waterjet:

Water costs

This factor is the most affordable, and is crucial to the entire process. Water is the only thing that can be cut with a waterjet. The amount of materials and the thickness of the material will determine how much water you use. The time it takes to cut thicker materials will be longer so you’ll need more water.

On average, 1000 gallons can be purchased for $3.51. If your cutting needs 5000 gallons of water, you will spend $17.55 on water. You may need a smaller or larger amount of water depending on what material you are cutting and how thick it is. Water is therefore an important factor in waterjet cost.

Power costs

Waterjet can’t be powered by electricity alone. This is a major factor in the price of a waterjet. But unlike water, power costs more. Let’s do a little math. If your waterjet uses 1,000 kWh, electricity will cost you 7.46 cents/KWh. That’s $74.60. You’ll pay between $3,700 to $9,400 annually for a pump with 50HP or 125HP that runs for approximately 6 hours each day.

Wears cost

Waterjet, like other machines, can also be damaged. You should also consider the cost of replacement parts. You may need to replace focusing tubes, orifices, pump seals, as well as other parts. These parts can be calculated on an hourly basis. You might be paying between $5 and $22 an hour in this case. You could be spending between $7,700 to $32,000 annually.

Cost of an Abrasive

The cost of an abrasive is important if you need to cut hard materials. This is the most expensive factor when you use a waterjet. A typical garnet abrasive will cost between 22 and 30 Cents per pound. It all depends on how much you buy and what abrasive it is.

One of these types of garnet can be chosen. One is alluvial garnet, and the other is hard rock. Crushed rock is also known as hard rock garnet. It is used to reduce large garnet rocks into smaller mesh sizes. It cuts faster because it is sharper.

You can also mine alluvial garnet by digging into rivers and beaches. Because of the effects of the water’s natural forces, they are smaller. Alluvial garnet grains are round, so they cut slower. Mo is the hard rock abrasive.

The alluvial and hard rock abrasives are more expensive. You should expect a higher water jet cut rate if you use the hard rock abrasive.

On average, you will pay 25 cents for each pound. When using abrasives, you should also take into account the flow rate. You should expect to use 1 to 2 pounds per minute if you are cutting metal plates. You’d spend an average of $18-$36 per hour using abrasives. You’ll spend $110 to $220 if you use the abrasive six hours per day. This is $550 to $1,100 per week. It will cost you between $26,000 and $55,000 annually if you use it for one year. If you only need to cut soft materials, such as aluminum or plastics then you don’t need an abrasive.

How to calculate waterjet costs for a project

It’s easy to calculate how much waterjet cutting will cost. You can find online tools to help you calculate. There are a few factors that can influence the calculation. These factors include:

- Types of material

- Material thickness

- The material’s final width to be cut

- The length of the final material to be cut

An online calculator can be used to calculate your waterjet cost. The standard waterjet cost calculator takes into account factors such as the type and cost of the raw material, labor costs, the type of waterjet cutter, and other factors. This is multiplied by the average company standard rate to get an estimated cumulative waterjet cost.

These online calculators can only be used as a guide. Requesting an online quote is a better option than contacting manufacturing companies directly. You can receive a more customized estimate for your project by doing this.

Conclusion

Waterjet cutting can be used in many industries. A waterjet can be used to cut small parts or precise pieces and reduce the need for secondary finishing.