Since the last two years, you may have read articles or heard about the delivery delays that Chinese suppliers have been facing for some time. There could be many possible reasons for the delay in deliveries, and in this article, we will talk about which factors have affected the Chinese suppliers.

If you want to select a decent Chinese supplier during these times, it is best to check out JustChinaIt. Their China sourcing agency specialists have completed more than 100,000 prosperous deliveries. There are several reasons to choose this firm for China sourcing: reduction in costs, no storage fees, and decrease in shipping freight.

COVID-19 Pandemic

There is no doubt that the Covid-19 pandemic has hit many industries up to that extent, where some big companies have to shut down their business. In China, Guangdong is one province that is considered the country’s economic powerhouse, and it is also the fastest-growing and largest economy in respect of GDP. As there was a sudden surge of Covid-19 infection in that province, Chinese authorities took the severe idea to close down neighborhoods and companies to deter the infection from circulating rapidly.

In addition to that, workers at trading terminals got Covid-19 infection, which is another cause of delivery delays. The Yantian terminal, being the third-largest across the world, has to shut down for about seven days at the end of May. Besides that, there are some disruptions in a few provinces, such as Guangzhou and Shenzhen. Experts also say that this could be another reason for the Chinese suppliers to experience delivery delays.

Closing Shipping Ports

Here is another major factor that has contributed to the supply chain delays. Between the months of August and June, China abruptly shut down the shipping ports due to the fear of the Covid-19 outbreak. Even an article from Bloomberg has stated that about 77% of the ports all over the world are suffering lengthy turnabout duration.

There was a time where about 73 vessels were tied up in Los Angeles and Long Beach. Critical information from other reports also informs that at least 386 ships are tied off in the Shanghai and Ningbo ports. Besides that, these two terminals are some of the busiest shipping ports in the world. In these two terminals, about 45 carton ships and 228 cargo ships have been locked.

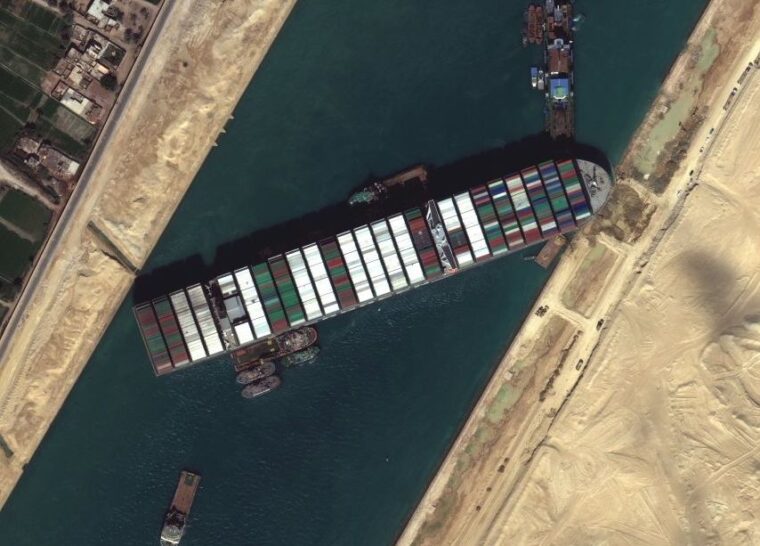

Suez Canal Blockage

The infamous Suez canal blockage not only affected the Chinese suppliers. But, it left a massive impact on the global supply chain. It began with the Ever Given, a large carton vessel that got stuck horizontally in the narrow route of the Suez Canal. It was even difficult for other ships to pass through this route because the container is relatively big and the Suez Canal route is thin.

In addition to that, it took about a week for workers from different countries to free the Ever Given ship. Though the ship was stuck for only a week, the impact lasted for over a month. It is because almost 12% of worldwide trade seeps through this canal. Due to this blockage, there was a heavy jam of the cargo ships, which usually transmit goods worth $10 billion daily.

Extreme Weather Conditions

Another factor that actually is affecting the supply chain of Chinese suppliers is the weather condition. For instance, extreme weather conditions like unexpected rainstorms in the ocean result in the loss of shipping containers. Due to that, the suppliers are canceling or postponing the deliveries in order to avoid losing the goods.

Tsunamis and cyclones also contribute to the shipping delays in China. Even if the sea transportation is completed without any problem, the goods that have to be delivered via road are delayed due to road blockages in several places. Overall, various kinds of weather, including storms, hurricanes, snow, and even bushfires, contributed to the shipping delays from China suppliers.

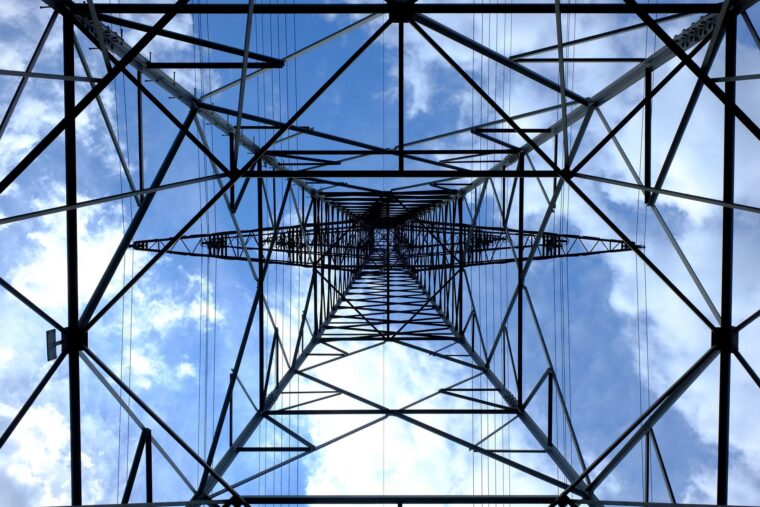

Power Outages

Chinese authorities have started power cuts to deter carbon emissions. As a result, manufacturing plants in various provinces in the country have reduced the total production or taken an extreme step of closing temporarily.

Because of the power outage, several industrialized provinces such as Zhejiang, Guangdong, and Jiangsu have faced a trade crisis. All the major shipping ports are also present in these provinces. During the power outage duration, it is actually a crucial period for Chinese suppliers as it is the busiest trading season for shipments to major markets such as European countries and the USA.

Shortage Of Shipping Containers In China

Here is another factor that is also the result of the pandemic. There were enough shipping containers previously, but with the outset of the Covid-19 infection, there was a sudden scarcity of shipping containers in China. Due to that, the shipping expenses became expensive, which further enhanced the rates of the goods. As a result, the deliveries face delays.

Abrupt Increase In Consumer Demand

After the trade was stopped for some months because of a pandemic, there was a sudden rise in the customer demand for various goods. As the Chinese suppliers are not totally ready because of the previous lockdown, the increase in delivery volumes has dazzled them. As they are in a hurry to manage several orders, sometimes they tend to miss essential details, which is one reason for the shipping delivery delays.

Conclusion

We took into consideration all the essential and even minor factors that have made Chinese suppliers experience delivery delays. As you can see, the pandemic has had a massive impact on the supply chain, not just in China but all over the world. Other factors like the Suez canal blockage, weather conditions, and scarcity of shipping containers, also have a significant effect on the delivery delays.